Your Source for Cutting-Edge Machinery Solutions

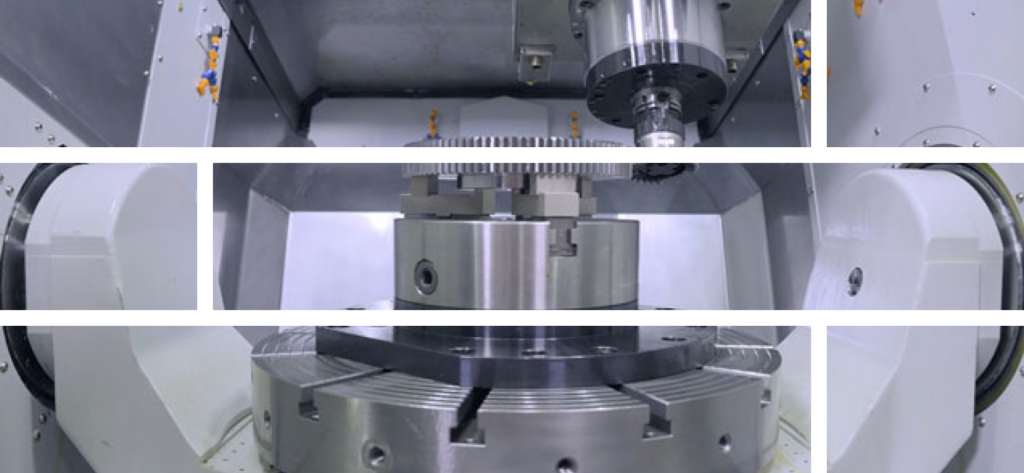

Twin spindle CNC chucker. Made for hard turning, high precision applications.

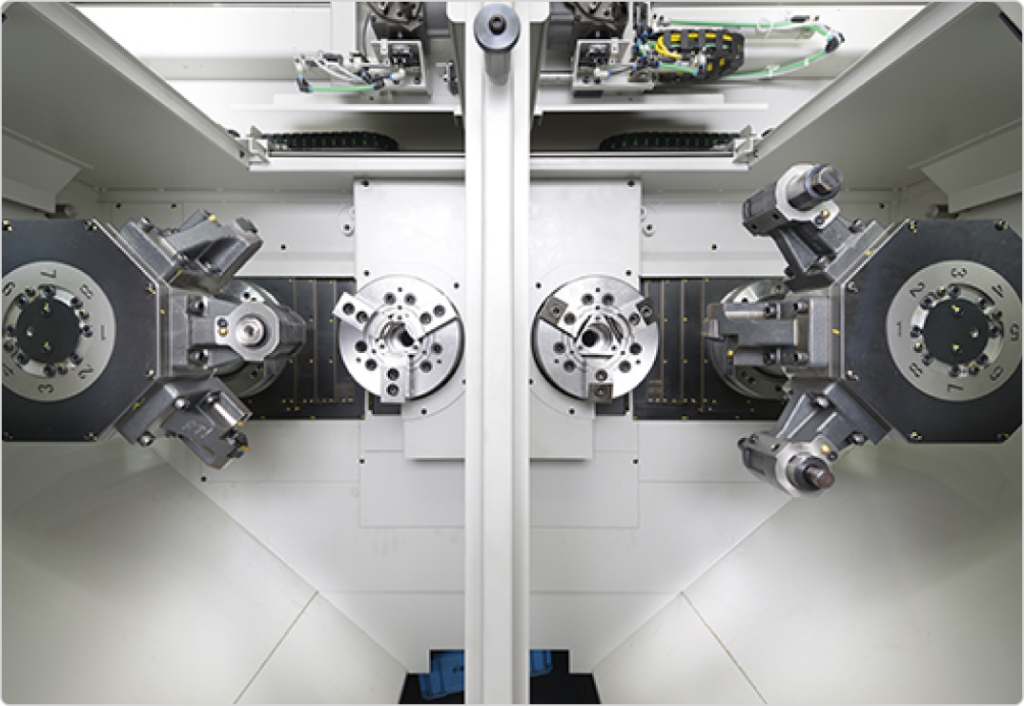

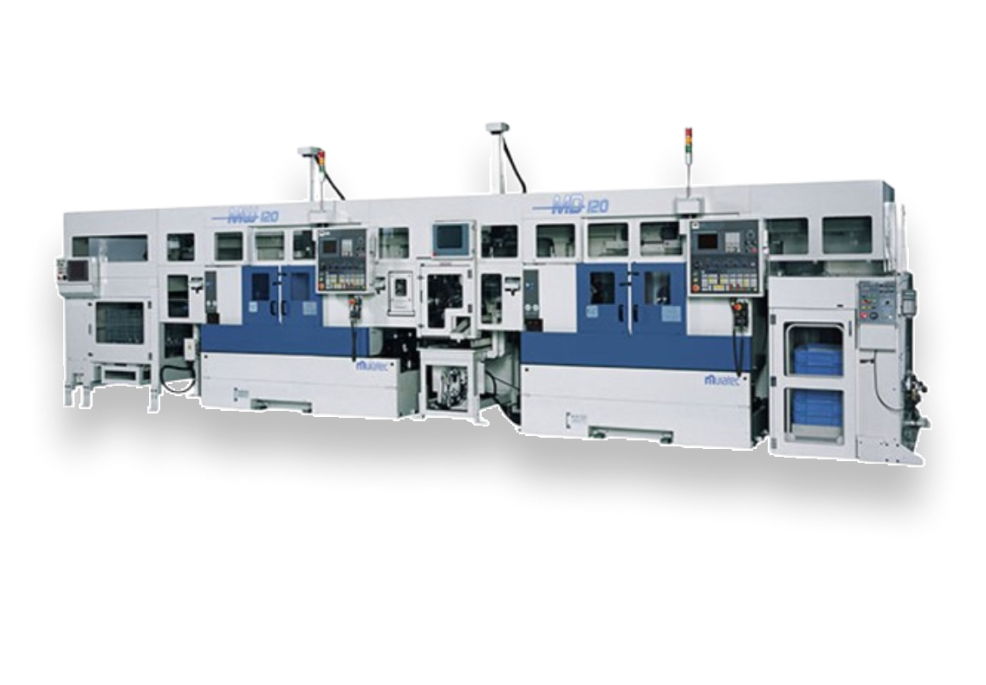

Twin spindle, high speed with 3-axis gantry loader.

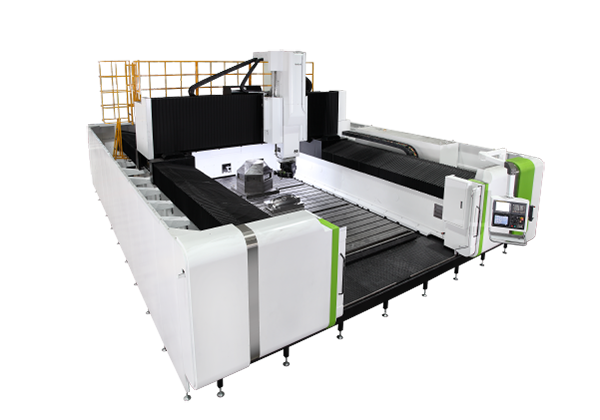

Feature Heavy